Whether you are commissioning a new set of tableware with a unique glaze design, or ordering a set of our classic cereal bowls in one of Honey Bee Hill's signature glaze patterns, you might be wondering why it can takes so long to receive your order. Let us break it down for you!

|

In the Beginning:

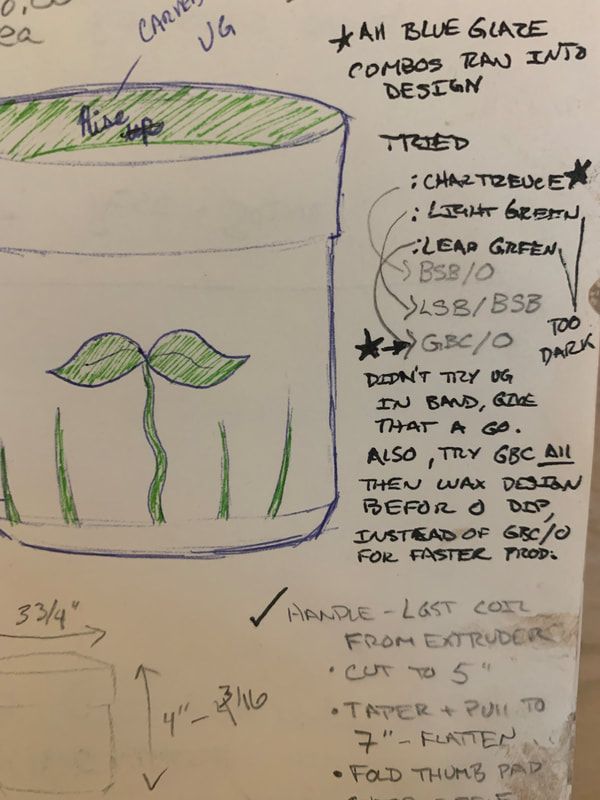

Whether designing for a client or updating our inventory with new products, experimentation is key. From idea to tangible product, it takes several goes at finding the right clay weight, shape of vessel, and layering of glazes to achieve a usable and beloved pot. The time it takes to move each test through the bisque kiln and the glaze kiln can take quite a few weeks. What's a bisque and glaze kiln, you ask. Read on! |

|

3. Trimming

After the objects have been left to slowly dry for anywhere from 1 to 5 days (drying too fast increases the risk of cracks or warping later on), Amanda trims the objects, does any carving that may be called for in the design, and cleans them up so that they are smooth and shapely. |

4. Handles On

If it's mugs or bowls with handles she's after, it's at this leather hard stage that Amanda will attach handles, a process which involves pulling the clay, shaping it, letting it too, to become leather hard, and then securing it to the body of the mug, followed by more slow and controlled drying. |

|

6. Glazing

Usually taking 3-5 days, glazing is a process of removing any dust that might get in the way of glaze adhering, applying glaze in various techniques and layers, and lastly cleaning a crisp edge at the foot of your pot to ensure each object appears cared for. During the 9-10 hour glaze fire, multiple layers of colored underglaze and/or glazes fuse together in the kiln to create dynamic effects through the chemical reaction that occurs when the metals & minerals of the glaze are bathed in high heat (2236*F). As most of our glazes appear to be some shade of beige while in liquid form, glazing is the most mysterious part of the process and the one in which we ultimately have the least control. What we can manage is knowing when the clay can take another layer and when we have to wait for the clay to absorb what's already been applied before moving on to the next layer. Weather, humidity, and temperature in the studio can greatly affect whether the pots can be glazed in one day or two and how they will appear upon completion. Once turned on, the kiln will need another two days to both reach the required temperature and then slowly cool back to room temperature ensuring it is safe to open the kiln and remove the pots without cracking. |

|

So, To Review:

Keeping in mind that the design process can be several iterations of throwing and glazing to finalize design, once a pot has been fully designed it must:

|

|